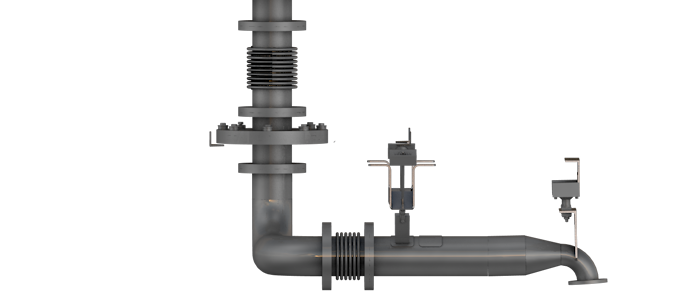

Stainless steel compensators are used in appliances, machines, apparatus and pipe systems where space is restricted:

Structure

Axces stainless steel bellows are available in a variety of structures and versions. The steel bellows is the flexible ele- ment of every compensator. It must fulfil the requirement for good movability with simultaneous pressure resistance.

Variable parameters (wall thickness, number of plies, convolution geometry, number of convolutions) determine the pressure resistance, movement absorption and spring rate (self- resisting force) of the bellows. Oneply, two-ply and multiply bellows are manufactured from various materials with different wall thicknesses.

The calculation methods ascertain the stability limits. The ability to withstand buckling is the prime criterion for smaller bellows diameters, whereas in larger bellows diameters it is convolution stability.

Material qualities

Axces compensator bellows are manufactured from top quality sheet metal. Different material qualities are used to cover the many operating conditions in various industrial applications.

The outstanding characteristic of the steels and alloys is their resistance to chemically aggressive liquid media. Please ask our Technical Consulting Service for detailed information about the media resistance of individual materials.

Stainless steel bellows, as a rule, are rated for a temperature of +20 ° C, the nominal pressure, and a load of 1000 load cycles. One load cycle refers to the procedure beginning at zero position, from where the compensator moves to the maximum elongation (positive) position, back through the zero position to the maximum compression (negative) position, and back to the zero position.

Together with the tolerable operating conditions.

• Pressure • Temperature

• Movement • Number of load cycles

The following parameters can also influence the service life of compensators:

Corrosion can be caused by incorrect selection or combination of materials, conveyance of aggressive media and inappropriate cleaning with chemical agents.

High-frequency oscillations and sympathetic vibration must be avoided, because this will result in fatigue failure/fracture. Pressure and temperature shocks must be avoided. It is important not to exceed the permitted maximum values.

Incorrect installation can be prevented by compliance with the installation and assembly instructions. In the case of unrestrained compensators, the absence of fixed points can cause the pipeline to shift. This usually destroys the compensator.

Connection parts

Axces compensators are supplied ready for installation. They are connected to pipes and fittings, by flanges, welding ends or threaded connections.

The connections are standardized to fit commercially available flanges, threads, and pipes.

Flanges

Stainless steel compensators can be supplied with rotating flanges or fixed flanges. Standard flanges are drilled in accordance to DIN2573 PN6.

Standard screws can be used because the flanges are drilled for standard bolts. Other flange connections under DIN, ANSI, JIS are also available.

Axces BV

Ondernemersweg 12

4691 SL Tholen

The Netherlands

Phone: +31(0)166 603 285

Email: info@axces.com

Copyright Axces 2021