There are numerous functional requirements that should be considered when designing a silencer for a specific application. Such functional requirements may include adequate insertion loss, back pressure, size, durability, desired sound, cost, shape and style. These functional requirements are detailed below focusing on an muffler’s functional requirements.

Insertion Loss and Transmission Loss

The main function of a silencer is to “silence” or attenuate sound. An effective silencer will reduce the sound pressure of the noise source to the required level. In the case of an industrial muffler the noise in the exhaust system, generated by the engine, is to be reduced.

A mufflers performance or attenuating capability is generally defined in terms of insertion loss or transmission loss. Insertion loss is defined as the difference between the acoustic power radiated without and with a muffler fitted. The transmission loss is defined as the difference in decibels between the sound power incident at the entry to the silencer to that transmitted by the silencer.

The silencer designer must determine the required insertion loss so that a suitable style of muffler can be designed for the specific purpose.

As a general principle when designing a muffler, a Reactive muffler with many area discontinuities will achieve a greater attenuation than one with fewer area discontinuities. The addition of sound absorptive material will always increase the attenuation capacity of a muffler, but should be located in an appropriate place.

Back Pressure

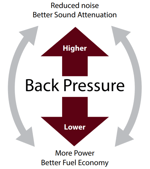

Back pressure represents the extra static pressure exerted by the muffler on the engine through the restriction in flow of exhaust gasses.

Generally, the better a muffler is at attenuating sound the more back pressure is generated. In a Reactive muffler where good attenuation is achieved, the exhaust gasses are forced to pass through numerous geometry changes and a fair amount of back pressure may be generated, which reduces the power output of the engine. Back pressure should be kept to a minimum to avoid power losses.

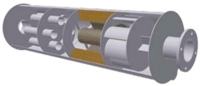

Every time the exhaust gasses are forced to change direction, additional back pressure is created. Therefore, to limit backpressure, geometric changes are to be kept to a minimum. A typical example of this is a “straight through” absorption silencer. Exhaust gasses are allowed to pass virtually unimpeded through the straight perforated pipe.

Durability

The life expectancy of a silencer is another important functional requirement, especially when dealing with hot exhaust gasses and absorptive silencers that are found in performance vehicles.

Overtime, hot exhaust gasses tend to clog the absorptive material with unburnt carbon particles or burn the absorptive material in the muffler. This causes the insertion loss to deteriorate. There are however, good products such as mineral wool, fibreglass, sintered metal composites and white wool that resist such unwanted effects.

Reactive type silencers with no absorptive material are very durable and their performance does not diminish with time.

Generally, silencers are made from corrosion resistive materials such as stainless steel. Mild steel is generally used for temperatures up to 500°C, type 409 stainless steel up to 700 °C and type 321 stainless steel for even higher temperatures. Diesel exhaust gas temperatures are usually around 550°C.

Shape and Style

Industrial silencers can be manufactured in all different shapes, styles and sizes depending on the desired application. Generally industrial silencers consist of an inlet and outlet tube separated by a larger chamber that is oval or round in geometry.

The inside detail of this larger chamber may be one of numerous constructions. The end user of silencers usually does not care what is inside this chamber as long as the muffler produces the desired sound and is aesthetically pleasing. It is therefore the task of the muffler designer to ensure that the muffler is functional as well as marketable.

Axces BV

Ondernemersweg 12

4691 SL Tholen

The Netherlands

Phone: +31(0)166 603 285

Email: info@axces.com

Copyright Axces 2021